Alloy Design Lab Research

Research

Fracture in extreme temperature condition

Fracture of steel in cryogenic and high-temperature environments is a critical issue in applications for extreme temperature conditions. We are researching the main reasons of fracture in extreme temperature conditions (cryogenic (~20 K) and high-temperature (> 800 ℃)). We aim to enhance our understanding of steel’s behavior in these demanding environments by investigating fracture mechanisms and characterizing microstructural changes. Furthermore, we try to suggest some methods to prevent the brittle fracture in extreme temperature conditions.

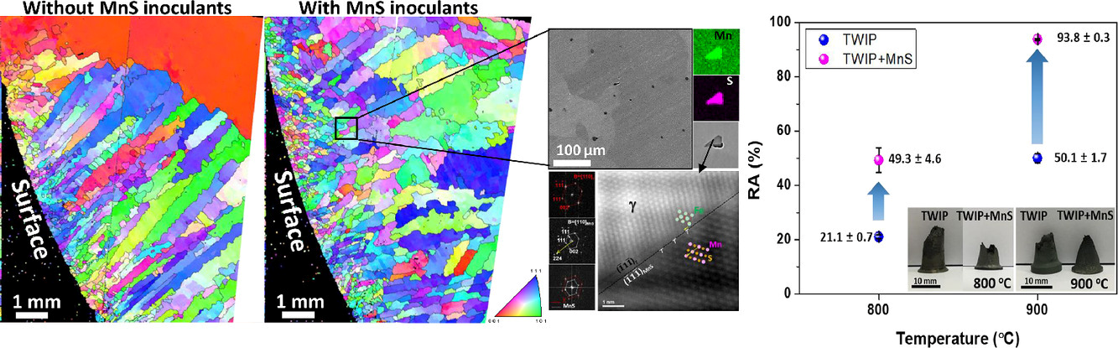

Improved hot ductility of TWIP steel via MnS inoculation

Improved hot ductility of TWIP steel via MnS inoculation

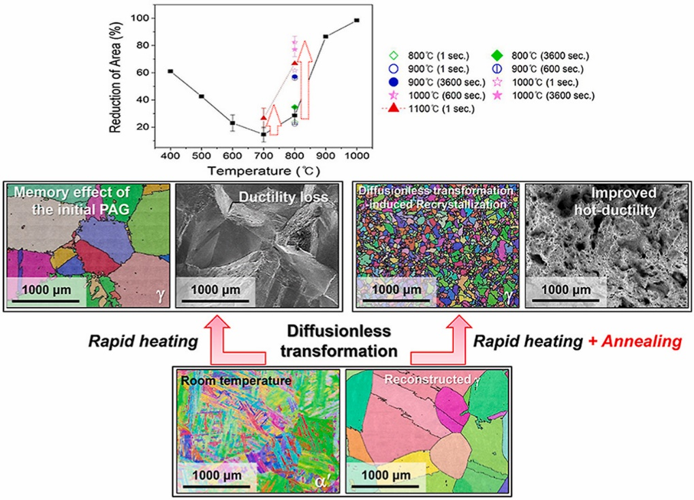

Improved hot ductility of high-Ni steel via recrystallization after diffusionless transformation

Improved hot ductility of high-Ni steel via recrystallization after diffusionless transformation

Brittle fracture (intergranular and cleavage fracture)

Brittle fractures can be divided into intergranular(IG) and cleavage fractures according to crack propagation paths. IG fractures in steels are generally related to the local segregation of impurities or precipitation of hard phases at the grain or phase boundary. The segregation behavior at the grain boundaries is not simply associated with exposing temperature and time but is complexly correlated with precipitation behaviors in a matrix and at the grain boundaries. We are researching the correlation between precipitation and segregation and trying to suggest mitigation strategies in various steel, such as lightweight steel, maraging steel, and bcc steel. Cleavage fracture is related to the relative strength difference between theoretical cleavage strength and shear strength. Thus, we investigate intrinsic modulus changes depending on alloying elements to clarify cleavage fracture.

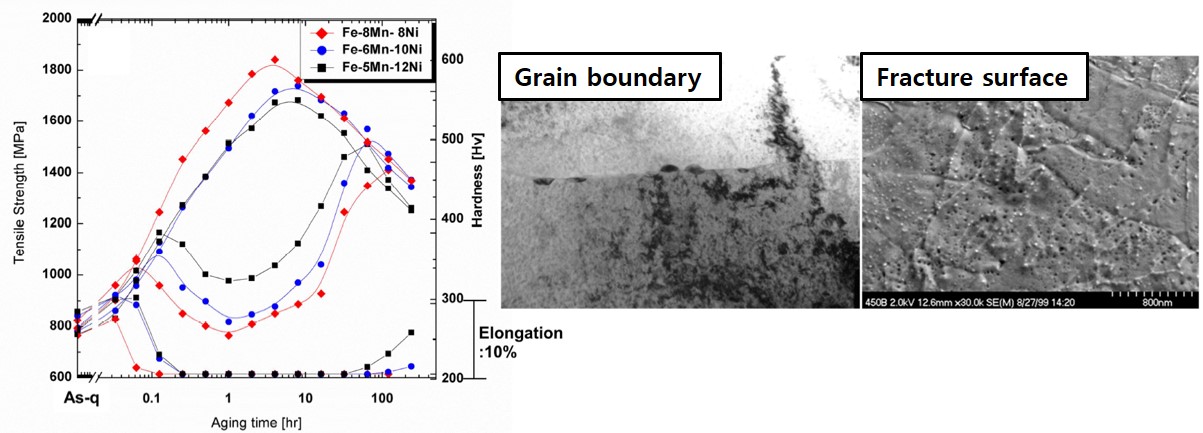

The intergranular fracture after aging by intermetallic compounds precipitation in maraging steel

The intergranular fracture after aging by intermetallic compounds precipitation in maraging steel

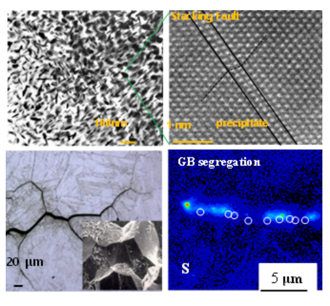

The intergranular fracture by S segregation in the steel

The intergranular fracture by S segregation in the steel