Alloy Design Lab Research

Research

Advanced Microstructure Characterization

The steel’s properties and performance can be interpreted by microstructure characterization through detailed examination and microscale analysis. It encompasses studying various microstructural features, such as grain boundaries, phases, and crystal defects. By utilizing advanced techniques such as in-situ experiments (in-situ tensile, in-situ heating) and atomic level characterization with Cs-corrected TEM, we are researching to find and interpret veiled mechanisms in various steel, such as TRIP steel, lightweight steel, maraging steel, and so on.

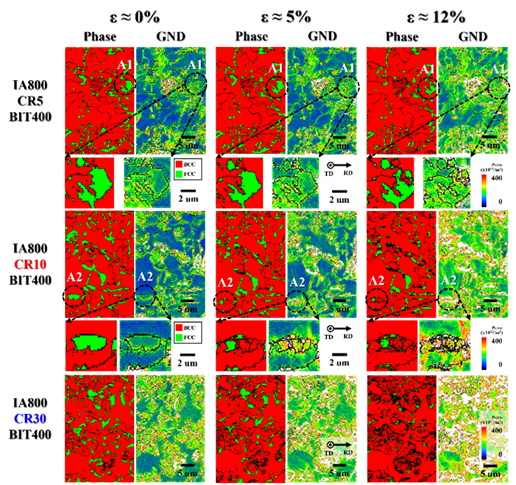

The microstructure evolution of TRIP steels with different cooling rate during tensile test

The microstructure evolution of TRIP steels with different cooling rate during tensile test

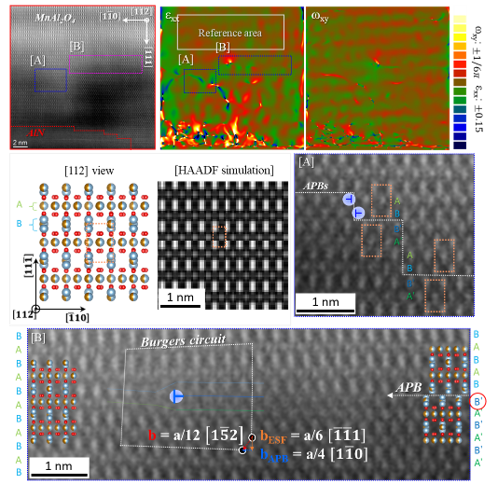

The formation of inverse-spinel MnAl2O4 in lightweight steel

The formation of inverse-spinel MnAl2O4 in lightweight steel

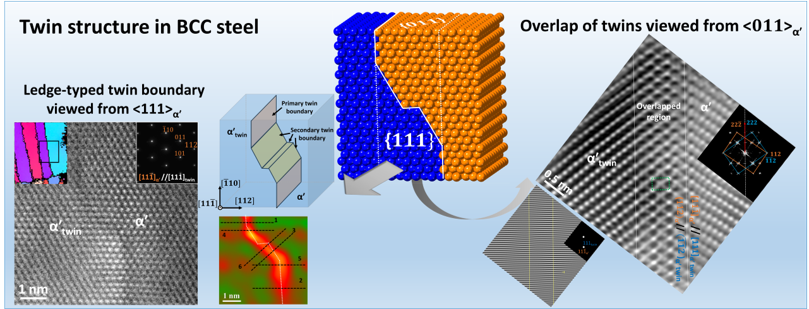

The evolution of ledge-typed twin boundary in bcc steel

The evolution of ledge-typed twin boundary in bcc steel

Surface characterization

In the automotive industry, reducing the weight of automobiles has been conducted to increase fuel efficiency. Since this endeavor has led to the substitution with high-strength steel, guaranteeing the corrosion resistance of high-strength steel sheets becomes pivotal in extending the quality assurance period. The corrosion resistance can be enhanced by additional coating, such as painting and conversion coating, and the coating quality is determined by surface characteristics. Therefore, we are researching the correlation of surface characteristics (surface microstructure, surface composition) with surface defects or coating quality. Also, through various methods, modifying surface characteristics to prevent the surface defect or to enhance the coating quality are conducted.

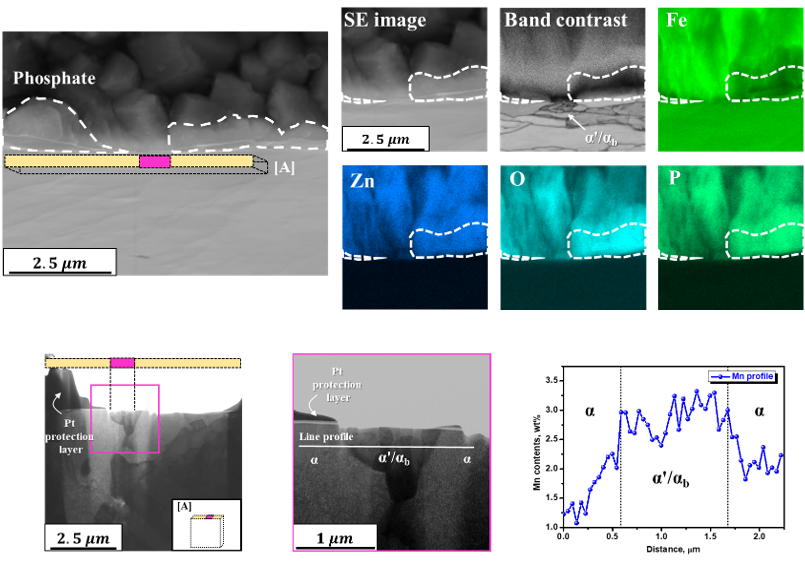

Cross-sectional analysis on the phosphate-missing area with using SEM and TEM

Cross-sectional analysis on the phosphate-missing area with using SEM and TEM